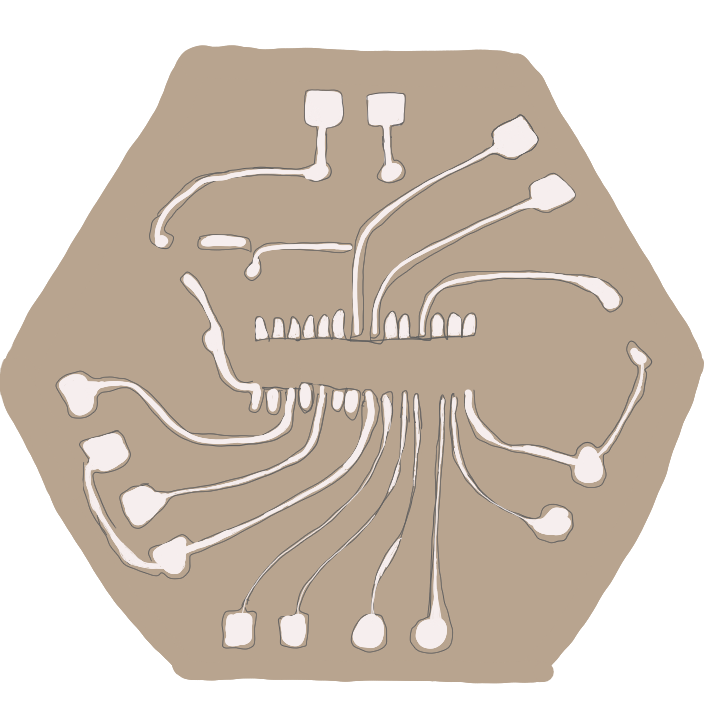

Clay PCB

Clay PCB Eco-feminist decolonial hardware

Stefanie Wuschitz (AT), Patrícia J. Reis (PT)

It is an open secret that the hardware in our smart devices contains not only plastics but also conflict minerals such as tungsten, tin, tantalum, silver and gold. Technology is not neutral. In this project we investigate alternative hardware from locally sourced materials, so-called ethical hardware, to develop and speculate upon renewable practices for the benefit of both nature and humans. We call it Feminist Hardware.

What is feminist hardware? We put together a set of rules that worked almost like an algorithm, served as a starting point to explore practices of resistance against current forms of exploitation and extraction for hardware production:

Feminist hardware is developed:

Without mining in harmful ways

Environmentally friendly

Under fair working conditions

Manufactured from ubiquitously available materials

Without generating e-waste

With love, consent and care

We conducted experiments on alternative assemblages for future and speculative technologies instigating debates on fair-traded, ethical, biodegradable hardware for environmental justice. In this sense, building circuits that use ancient community-centred crafts and knowledge as an artistic practice encourages de-colonial thinking, market forces to be disobeyed, and future technologies for the Chthulucene to be imagined. Our artistic outcome is an Ethical Hardware Kit — a speculative survival kit for the apocalypse — with a PCB microcontroller at its core. Our PCB is not made of plastic but instead clay retrieved from the forest in Austria and fired on a wood open fire. Our conductive tracks used urban-mined silver and all components are re-used from old electronic devices. The microcontroller can compute different inputs and outputs and is totally open source. Further instructions for Programming and soldering the components, 3D printing files, code are free access in our Tutorial page.

Check out our video:

Credits:

Concept and Design: Patrícia J. Reis & Stefanie Wuschitz

PCB Design: Patrícia J. Reis & Daniel Schatzmayr

3D Printing: Klemens Kohlweis

Clay research: Patrícia J. Reis